Real-time tracking delivers end-to-end visibility for expedited cross-border shipments, from origin pickup through border crossing and final delivery. GPS-based tracking and proactive status updates allow shippers to monitor progress, anticipate arrival times, and respond quickly to exceptions. This level of transparency is especially critical for time-sensitive freight, providing greater control and confidence throughout the process.

January 10, 2026 | BY Dan Boaz

Connecting Tennessee’s Automotive Industry with Mexico

Share this article

Tennessee has emerged as an automotive manufacturing powerhouse, home to major assembly plants and a vast network of over 900 suppliers across the state. From Nissan’s sprawling operations in Smyrna and Decherd to Volkswagen’s high-tech plant in Chattanooga and General Motors’ extensive facilities in Spring Hill, the Volunteer State produces hundreds of thousands of vehicles annually.

Keeping these production lines running on schedule requires a smooth flow of auto parts and components - and increasingly, those parts are coming from (and going to) Mexico. In fact, Mexico is Tennessee’s second-largest trading partner by volume, with automotive products dominating the trade. Every day, a steady stream of engines, transmissions, electronics, and other components moves between Tennessee and Mexican manufacturing hubs.

Lean operations leave little room for error or delay. A minor disruption - a late shipment, a border holdup, an unexpected equipment failure at a supplier’s plant - can quickly snowball into an assembly line shutdown. That’s why Tennessee’s automotive manufacturers and suppliers rely heavily on expedited freight services to ship to and from Mexico at a moment’s notice.

Hot shot trucking and dedicated air freight have become logistical cornerstones for the industry, ensuring that critical parts arrive on time even under tight deadlines. Whether it’s a last-minute rush delivery of sensors from Monterrey to Nashville or an urgent shipment of engine parts from a Knoxville supplier to a plant in Mexico, expedited transportation solutions are what keep production on track.

TENNESSEE’S STRATEGIC POSITION IN THE SUPPLY CHAIN

Located at the crossroads of the U.S. Southeast, Tennessee occupies a strategic sweet spot for automotive logistics. The state is crisscrossed by major interstates (I-40, I-24, I-65, I-75, and I-55) that link directly to key gateways. From Nashville or Chattanooga, a truck can head west to Texas or south to the Mexican border within a day’s drive, making long haul trucking to Mexico feasible on tight schedules. Memphis, in western Tennessee, is a particularly critical logistics hub – not only is it home to the nation’s busiest cargo airport (the FedEx SuperHub) for overnight freight, but it also lies along the primary trucking routes to Laredo, Texas, the largest U.S.–Mexico border crossing.

On an average day roughly 17,000 trucks cross the border at Laredo, many loaded with auto parts destined for or coming from manufacturing states like Tennessee. By tonnage and value, automotive components are the number one commodity moving through that port. This means Tennessee’s factories have a direct pipeline to Mexico’s automotive cluster via the ground transportation network.

TALK TO AN EXPEDITOR NOW

Get a Free Freight Quote Now

The Tennessee Automotive Industry

- Scale of Automotive Production - Tennessee’s automotive industry operates at significant scale, employing tens of thousands of workers and generating billions of dollars in annual output. Assembly plants and suppliers across the state require a constant, high-volume flow of components to sustain production. This scale creates continuous demand for fast, reliable freight movement, particularly for time-sensitive automotive parts.

- Heavy Two-Way Trade with Mexico - Mexico is one of Tennessee’s most important automotive trade partners. Large volumes of engines, transmissions, electronics, and subassemblies move from Tennessee to Mexican plants, while an even greater volume of parts and finished vehicles flows north into Tennessee assembly operations in Smyrna, Spring Hill, and Chattanooga. This bidirectional movement increases exposure to disruption and elevates the importance of dependable cross-border transportation.

- Dependence on Expedited Logistics - Because production on both sides of the border must remain tightly synchronized, transportation delays carry immediate consequences. A late truck, a missed border transfer, or a customs delay can interrupt assembly schedules in either country. To mitigate this risk, Tennessee-based manufacturers rely heavily on expedited trucking and priority freight solutions, ensuring the Tennessee–Mexico corridor remains fast, flexible, and resilient under pressure.

Why the Auto Industry Needs Expedited Freight

The automotive industry operates under extreme time sensitivity, where production efficiency depends on precise coordination across global supply chains. Modern assembly plants are designed to minimize inventory, maximize throughput, and respond quickly to market demand. In this environment, even minor disruptions can escalate into costly shutdowns.

Just-in-Time Production Leaves No Margin for Delay

The Cost of Downtime Far Exceeds Shipping Premiums

Supply Chain Disruptions Are Inevitable

Increasing Component Complexity Raises Risk

Global and Cross-Border Manufacturing Demands Speed

Flexibility to Respond in Real Time

Protection of Brand Reputation and Customer Commitments

Just-in-Time Manufacturing and Expedited Cross-Border Logistics

Automotive manufacturing in Tennessee operates on a just-in-time (JIT) production model, where efficiency is driven by precision rather than inventory buffers. Assembly plants no longer stockpile weeks’ worth of components; instead, parts are scheduled to arrive exactly when they are needed on the production line, often within narrow hourly windows. This model reduces carrying costs and improves responsiveness, but it also leaves little margin for error.

For manufacturers and suppliers moving freight between Tennessee and Mexico, JIT manufacturing raises the stakes considerably. Industry estimates place the cost of an idle automotive production line at tens of thousands of dollars per minute, making supply chain interruptions extraordinarily expensive.

Expedited Logistics as a Safeguard for JIT Production

When standard transportation schedules cannot meet production timelines, manufacturers turn to expedited logistics to prevent line stoppages. These situations arise frequently due to unplanned events such as equipment failures, quality issues, supplier delays, or congestion at border crossings. In a JIT environment, even a minor disruption can escalate quickly into a production-critical emergency.

In practice, this often means switching instantly from routine freight movements to priority shipping. A component that would normally move on a consolidated weekly truck may instead be dispatched via a dedicated hot shot vehicle or placed on the next available flight.

Expedited Trucking Between Tennessee and Mexico

For urgent ground transportation, expedited trucking—often referred to as hot shot service—is a cornerstone of cross-border automotive logistics. These shipments move on dedicated vehicles that travel directly from origin to destination without intermediate stops or cargo consolidation. By eliminating detours and handling delays, hot shot trucks dramatically reduce transit times and improve reliability.

Expedited carriers deploy a range of equipment depending on shipment size and urgency. Sprinter vans and heavy-duty pickups with gooseneck trailers are common for smaller loads, offering speed, maneuverability, and smoother border crossings.

Air Freight as the Ultimate Time-Critical Option

When ground transportation cannot meet the required timeline, air freight provides an additional layer of speed and flexibility. For high-value or production-critical components, air cargo can compress transit times from days to hours. Tennessee manufacturers routinely leverage air freight when the financial impact of downtime outweighs the premium cost of flying parts.

Several air freight strategies are commonly used. Air charters offer the fastest solution, with dedicated aircraft flying direct routes as soon as cargo is ready. These charters can utilize secondary airports near manufacturing sites, further reducing total transit time. Another widely used option is Next Flight Out (NFO), which places urgent shipments on the first available commercial flight, often using passenger aircraft belly space or scheduled cargo services.

Managing Cross-Border Complexity and Risk

Expedited shipping between Tennessee and Mexico requires more than fast vehicles—it demands meticulous cross-border coordination. Customs compliance, security protocols, and regulatory documentation all introduce potential friction points that can undermine even the fastest transportation plan. As a result, experienced freight brokers and third-party logistics providers play a central role in managing these shipments.

Effective providers ensure that all documentation, including commercial invoices and USMCA certificates, is prepared and validated in advance.

Discover the advantages of hot shot trucking with a trusted partner delivering reliable, expedited freight solutions across the United States.

Expedited Trucking Network from Tennessee to Mexico

A specialized expedited carrier network is critical for moving time-sensitive freight without delay. Access to vetted hot shot carriers, team drivers, and dedicated expedited equipment enables rapid response when production-critical shipments must move immediately. From pickup at manufacturing plants or distribution centers to delivery into automotive and industrial regions, our partners operate on direct routes, ensuring the fastest possible transit times.

EXPLORE OUR COVERAGEDedicated Cross-Border Expediting Coordination

Managing expedited cross-border freight is simplified through a single, dedicated expediting point of contact. Centralized coordination ensures seamless communication across carriers, customs brokers, reducing delays and misalignment at the border. With one accountable expeditor overseeing the shipment from pickup through final delivery, expedited cross-border moves remain efficient, controlled, and responsive to changing conditions.

MEET THE TEAM

24/7 Support for Cross-Border Expedited Freight

Cross-border expedited shipments often move outside standard business hours and require immediate action when conditions change. Around-the-clock support ensures urgent trucking needs, border delays, or capacity shifts are addressed in real time. Continuous availability allows expedited freight to be rerouted, recovered, or accelerated as needed, helping shippers maintain production schedules and avoid costly downtime.

VIEW ALL SERVICES

Future Outlook: The Tennessee–Mexico Automotive Corridor

- Expanding Cross-Border Production

- Time-Critical Logistics

- Infrastructure and Technology Advancements

- Continued Strategic Role of Air Freight

- Deeper Integration

- Resilient and Competitive

Expanding Cross-Border Production and Freight Volumes

Automotive manufacturing growth in both Tennessee and Mexico is driving a steady increase in cross-border freight flows. Mexico continues to strengthen its role as a key production hub for engines, electronics, and subassemblies, while Tennessee attracts new investments in vehicle assembly, electric vehicles, batteries, and advanced components. As a result, more high-value and production-critical parts will move between the two regions, reinforcing the need for reliable, fast transportation options that can support continuous production without inventory buffers.

Intensification of Time-Critical Logistics Requirements

Just-in-time delivery models are expected to persist and, in some cases, become more demanding. The transition to electric vehicles introduces new risk profiles, particularly for batteries and powertrain electronics, where quality issues or supply disruptions can halt production rapidly. In these scenarios, expedited logistics will play a central role in mitigating downtime, enabling rapid replacement of components before line stoppages occur and preserving manufacturing continuity.

Infrastructure and Technology Advancements

Logistics infrastructure and service capabilities are evolving to support higher-speed cross-border movement. Investments in customs pre-clearance programs, expanded port-of-entry capacity, and improved border technologies are aimed at reducing delays at key gateways. At the same time, carriers are expanding expedited fleets, including sprinter vans, team-driven trucks, and specialized equipment. Advanced tracking and AI-driven logistics platforms are improving visibility and decision-making, allowing supply chain managers to identify risks early and deploy expedited solutions proactively rather than reactively.

Continued Strategic Role of Air Freight

Air freight is expected to remain a critical component of automotive logistics, particularly for high-value or highly time-sensitive components. As demand grows, dedicated or semi-regular air cargo routes between Mexico and the U.S. Southeast may emerge, providing predictable overnight capacity for automotive parts. While sustainability considerations may influence future equipment choices, speed and reliability will continue to outweigh cost and environmental trade-offs in production-critical scenarios.

Deeper Integration Between Manufacturers and Logistics Providers

The growing complexity of cross-border automotive supply chains is driving closer collaboration between manufacturers and logistics providers. Expedited carriers, 3PLs, and air freight specialists are increasingly engaged at a strategic level, helping design resilient supply chains rather than simply responding to emergencies. Some manufacturers are pre-contracting expedited trucking and air charter capacity as contingency resources, ensuring rapid response when disruptions occur.

A Resilient and Competitive Automotive Corridor

Tennessee’s geographic position and manufacturing base have established it as a vital link in North America’s automotive supply chain, tightly interconnected with Mexico’s production network. Expedited trucking and air freight serve as essential enablers, ensuring that borders and distance do not compromise production speed or reliability. As the industry evolves, the Tennessee–Mexico corridor is positioned to set a benchmark for responsiveness and resilience, allowing manufacturers to maintain momentum in an increasingly fast-paced and unforgiving production environment.

The Right Capacity Is Key to Every Urgent Shipment

Your urgent shipment will be the only freight in the Sprinter van, box truck, straight truck, hot shot truck, 53’ dry van, or full flatbed to minimize damage and ensure the shipment goes direct from pickup to delivery.

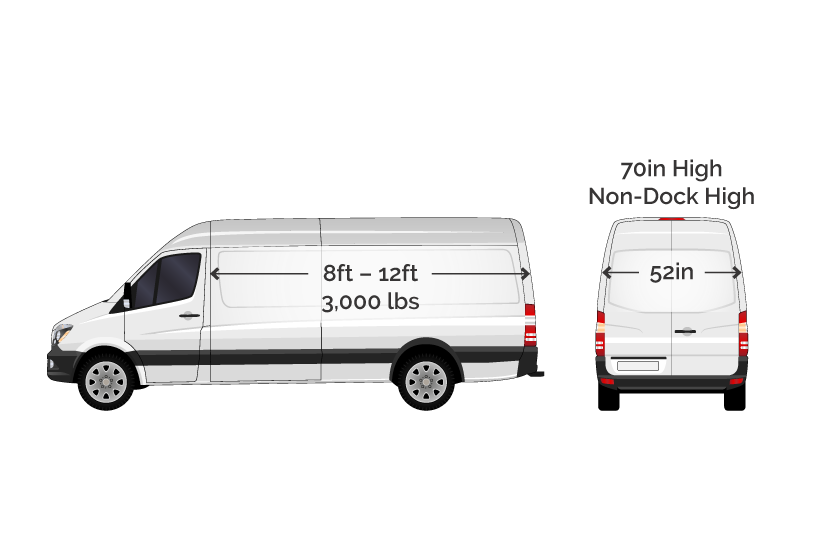

SPRINTER VAN

HotShotTrucking.com's network of expedited Sprinter vans have the capacity to meet your local, regional, or long-distance ground shipping needs. Measuring 8-12’ x 52” x 70", our carefully-selected vans have the capacity to carry loads up to 3,000 lbs.

#1

4.9/5

50000

24/7

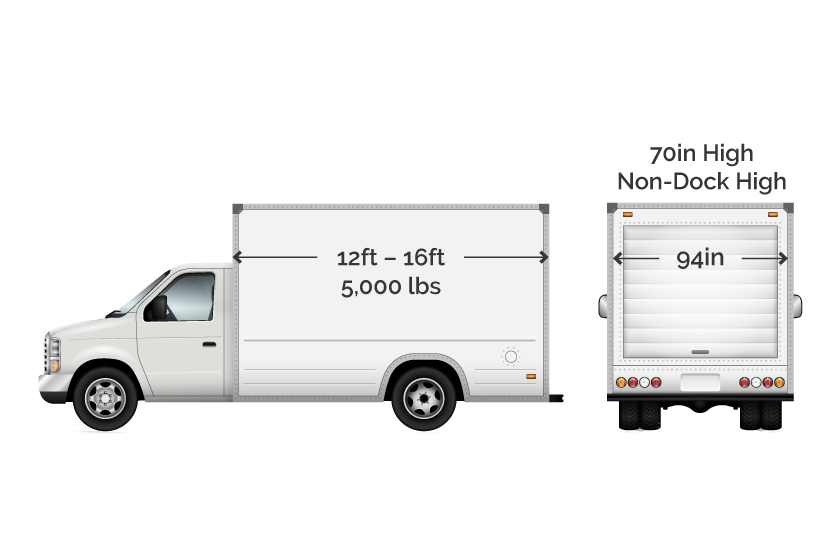

BOX TRUCK

We pride ourselves in working with trusted partners that offer carefully-vetted box trucks, from lift-gate service to varying sizes that accommodate smaller loads. Box trucks, or small straight trucks, measure 12-16’ x 94” x 70” and have the capacity to carry up to 5,000 pounds.

#1

4.9/5

50000

24/7

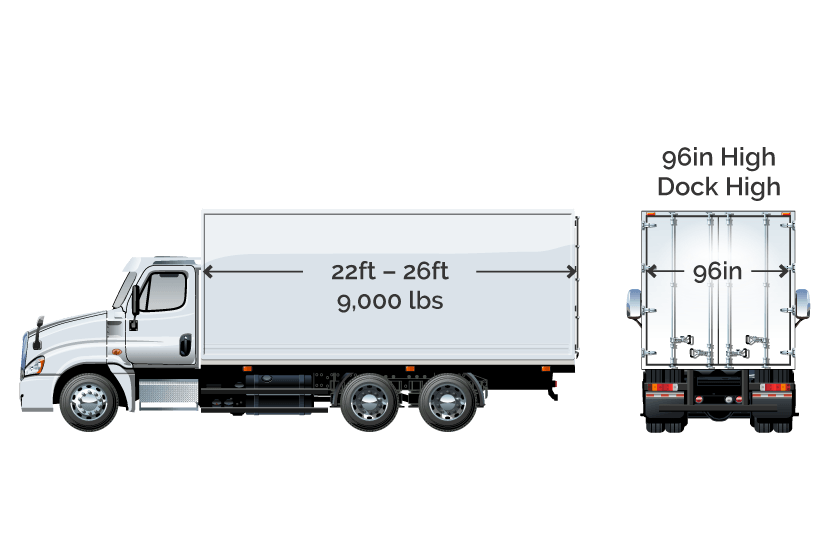

STRAIGHT TRUCK

Measuring 22-26’ x 96” x 96”, straight trucks can carry loads up to 9,000 pounds. Large straight truck services offer focused logistics, professional drivers, and deeply-experienced expeditors to get your delivery where it needs to go.

#1

4.9/5

50000

24/7

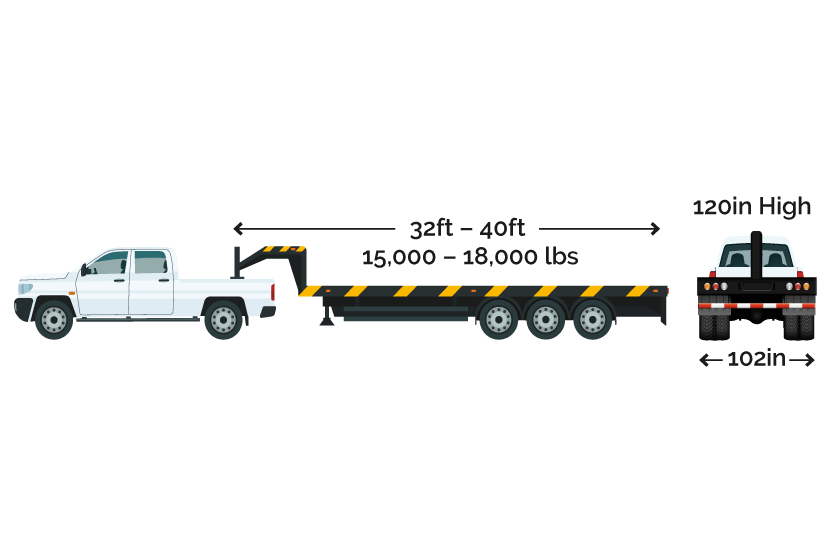

HOT SHOT TRUCK

We'll happily arrange for your freight to be transported via hot shot trucking services. We've proudly partnered with hot shot trucking providers across North America to give you access to carefully-vetted ground delivery vehicles for your time-critical freight.

#1

4.9/5

50000

24/7

53' DRY VAN

Our premium network of 53-ft dry vans can carry loads up to 42,000 pounds. Measuring 53’ x 99” x 102”, these carefully-vetted vehicles will ensure your time-sensitive freight arrives at its destination safely.

#1

4.9/5

50000

24/7

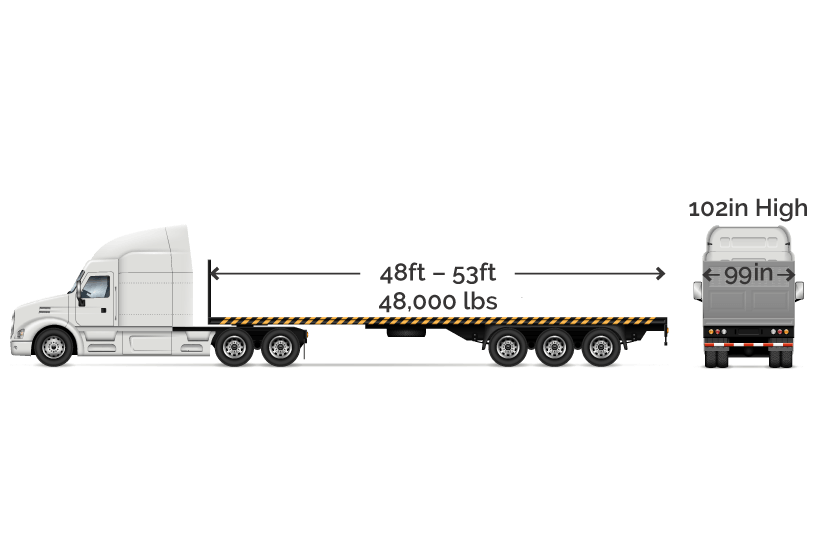

FULL FLATBED

HotShotTrucking.com's network of full flat bed vehicles can accommodate wide or mega-size loads, such as specialized equipment machinery of all weights and sizes. Measuring 48-53’ x 102” x 102”, full flat bed vehicles can carry freight of up to 48,000 pounds.

#1

4.9/5

50000

24/7

Frequently Asked Questions

What is hot shot trucking, and how does it benefit automotive supply chains?

Hot shot trucking is an expedited freight service that uses smaller, specialized trucks—typically Class 3–5 vehicles pulling flatbed or enclosed trailers—to move time-sensitive shipments quickly and directly. In automotive supply chains, it is commonly used for urgent components, tooling, or subassemblies that must reach a plant without delay. Because hot shot carriers operate with fewer constraints than traditional long-haul trucking, they can be dispatched rapidly and routed point-to-point.

For automotive manufacturers and Tier 1/Tier 2 suppliers, the primary benefit is speed and flexibility. Hot shot trucking helps prevent production disruptions by supporting just-in-time (JIT) and just-in-sequence (JIS) operations, reducing the risk of line stoppages when parts are late, damaged, or unexpectedly short.

How does hot shot trucking differ from standard trucking or regular freight shipping?

The key difference lies in urgency, scale, and routing. Standard trucking and LTL freight typically operate on fixed schedules, consolidated loads, and hub-and-spoke networks. Hot shot trucking, by contrast, is designed for immediate dispatch, smaller shipment sizes, and direct delivery without cross-docking or consolidation.

Additionally, hot shot trucking offers greater responsiveness to last-minute changes. Automotive shippers use it when transit time matters more than cost efficiency, such as when a production line is at risk or when a replacement part must arrive within hours rather than days.

What types of automotive freight are typically moved via hot shot trucking?

Hot shot trucking is commonly used for high-value, time-critical automotive components. These include powertrain parts, electronic modules, sensors, stamping dies, tooling, prototype parts, and replacement components needed to resolve quality issues or supplier disruptions.

It is also frequently used for launch-phase materials, engineering samples, and emergency replenishment of parts that support JIT manufacturing. The freight is often compact but essential—items that can halt an entire assembly line if they do not arrive on time.

What are the benefits of using expedited freight for just-in-time manufacturing in the automotive industry?

Expedited freight enables automotive manufacturers to maintain low inventory levels while still protecting production continuity. By accelerating transit times, manufacturers can respond quickly to demand variability, supplier delays, or transportation disruptions without carrying excess safety stock.

In JIT environments, even minor delays can have cascading effects. Expedited freight serves as a risk-mitigation tool, allowing plants to recover quickly from supply chain shocks while preserving the cost and efficiency advantages of lean manufacturing.

What role does just-in-time (JIT) manufacturing play in Tennessee’s automotive logistics strategy?

Tennessee’s automotive industry—home to major OEMs and suppliers—relies heavily on JIT manufacturing to remain competitive. Plants are strategically located near interstate corridors, rail hubs, and logistics providers to support frequent, precisely timed inbound deliveries.

JIT reduces warehousing requirements and improves cash flow, but it also increases dependence on reliable transportation. As a result, expedited trucking, hot shot services, and cross-border logistics capabilities are integral to Tennessee’s broader automotive logistics strategy.

How do logistics providers respond to emergency part shortages or “line-down” situations in auto manufacturing?

In line-down scenarios, logistics providers prioritize immediate action and direct communication. They identify the fastest available transportation option—often hot shot or team-driven expedited trucking—and dispatch equipment as soon as the freight is released.

Providers also coordinate closely with plant logistics teams to align delivery timing, dock availability, and after-hours receiving if needed. In many cases, contingency plans and pre-approved carriers are already in place to reduce response time when emergencies occur.

How do cross-border logistics work between Tennessee’s automotive plants and suppliers in Mexico?

Cross-border automotive logistics typically involve coordinated movements between Mexican suppliers, border transfer points, and U.S. carriers. Freight may move via dedicated expedited trucks or relayed through bonded carriers at the border to maintain compliance and speed.

Tennessee plants often rely on established northbound corridors through Texas or Arizona, supported by customs brokers and logistics providers experienced in automotive freight. Timing is critical, particularly for JIT shipments, so routes and border crossings are selected based on reliability as much as distance.

How are customs and border clearance handled for expedited shipments between the U.S. and Mexico?

For expedited shipments, customs clearance is typically pre-arranged before the freight reaches the border. Documentation such as commercial invoices, USMCA certificates of origin, and packing lists are submitted in advance to minimize delays.

Many logistics providers use bonded carriers, in-bond movements, or fast-lane border programs to accelerate clearance. Close coordination between customs brokers, carriers, and shippers is essential to ensure that expedited freight does not lose time at the border.

How can shippers ensure compliance with customs regulations for U.S.–Mexico auto parts shipments?

Compliance begins with accurate documentation and classification. Shippers must ensure correct HS codes, declared values, country-of-origin data, and USMCA eligibility where applicable. Errors in any of these areas can result in costly delays, even for expedited freight.

Working with experienced customs brokers and logistics partners is critical. Many automotive shippers also conduct periodic compliance audits and maintain standardized documentation processes to reduce risk during urgent or high-frequency cross-border shipments.

How is an expedited shipment coordinated from a Mexican supplier to a Tennessee assembly line?

Coordination typically starts with immediate pickup at the Mexican supplier, often within hours of release. The logistics provider arranges transportation, confirms documentation, and aligns border-crossing plans before the truck departs to avoid mid-transit delays.

Once cleared at the border, the shipment moves directly to the Tennessee assembly plant using team drivers or hot shot equipment if required. Throughout the process, real-time tracking and proactive communication keep plant logistics teams informed, ensuring the freight arrives precisely when the assembly line needs it.

Related Blog Posts

Truckload Demand Remains Higher than this Time Last Year

Based on the latest reports on durable goods manufacturers’ shipments, orders and inventories, freight volume has yet to decline. The most recent numbers from the US Census Bureau show that orders for manufactured durable goods increased in May by 0.7% to $267.2 billion. This follows increases for seven of the past eight months. This May, shipments of manufactured durable goods increased by $3.6 billion or 1.3%, followed by a 0.3 % rise in...

Regulatory and Legislative Update - May 2024

Regulatory and legislative news for May 2024 includes the FMCSA renewing consideration of knowledge/proficiency exams for carriers and brokers, the FMCSA inviting comments on its plan for a new online registration platform and Hawaii seeking exemption on student transportation options. The FMCSA is also set to revise a younger driver pilot program. Contents Regulation and Enforcement FMCSA formally drops certain conditions for younger driver...

Louisiana's Transportation Plan To Benefit Hot Shot Trucking Industry

After years of discussion and debate from countless stakeholders, Louisiana is starting a new infrastructure project. Governor John Bel Edwards unveiled a $600 million plan to improve the state’s highways. Focusing on widening Interstate 10, this plan will be a boon to Hot Shot Trucking and other transportation companies that traverse the state. Governor Edwards announced the plan on Friday, May 13th, claiming that it was “of the utmost...

The Advantages of Hot Shot Trucking for Small Businesses

In the world of logistics, small businesses often face unique challenges when it comes to shipping their products efficiently and cost-effectively. This is where hot shot trucking can be a game-changer. Hot shot trucking offers a range of advantages that can significantly benefit small businesses, enabling them to compete in the marketplace and meet customer demands. In this blog post, we will explore the advantages of hot shot trucking for...

How Highway Closure Impacts Hot Shot Trucking California

Natural disasters can disrupt any industry, but their impact is particularly serious for logistics companies. The recent mudslides in California are a powerful case in point. By blocking Highway 101, one of the Golden State’s most important roadways, this environmental crisis has diverted trucks from their usual routes. This has significantly increased the cost and difficulty of completing hot shot freight deliveries, hampering the economy of...

Essential Tips for Successful Hot Shot Trucking

Running a successful hot shot trucking business requires a combination of effective strategies, attention to detail, and a commitment to customer satisfaction. Whether you're a new entrant or an experienced hot shot trucker, adopting essential tips can help you navigate the industry and increase your chances of success. In this blog post, we will provide practical advice and strategies for running a thriving hot shot trucking business, covering...

House Bill 7095 / Section 4202

House panel to vote on bill with measures on CSA, SFD, HOS The Democratic leadership of the House Transportation & Infrastructure Committee on June 4 introduced legislation (H.R. 7095) to reauthorize transportation programs following the expiration of the FAST Act on September 30. Title IV of the bill addresses motor carrier safety and includes several significant provisions related to Federal Motor Carrier Safety Administration (FMCSA)...

747 Freighter Air Charter to Hawaii

When it comes to providing air cargo capabilities, there is no aircraft in the world that compares with the Boeing 747 series of freighters. All three 747-400F, 747-400ERF and 747-8F freighter models in service today, are unmatched in carrying capacity, cargo handling, global reach, speed and versatility. An aviation icon born in 1968, the 747 is instantly recognizable by its large upper deck “hump”, four engines and six-story high vertical...

Shipping Kansas City to St Louis: Thinking Outside the Box

This is just one more example of how our team’s creative problem-solving and extensive experience can truly make a difference for our clients. We’ve built a strong relationship with one of our regular customers who specializes in creating custom displays for retail stores. As the holiday shopping season kicked into full gear, they found themselves under tight pressure to complete a project. It was early December, and with the holiday rush...

Regulatory and Legislative Update - September 2024

Contents Regulation and Enforcement House panel approves bill to address FMCSA’s commercial enforcement House panel advances bill granting carrier access to driver safety history Regulation and Enforcement FMCSA once again seeks input on plan to revamp online registration FMCSA seeks input by September 26 on its periodic review of guidance documents Truck Leasing Task Force to meet in October and November FMCSA removes two devices from list of...

Regulatory and Legislative Update - October 2024

Contents Legislation Speed limiters, preemption, and Norton bill await possible lame duck action DOT Funding Bill Additional States Considering California Type CARB Restrictions Regulation and Enforcement Significant FMCSA regulation is limited before the next administration FMCSA Registration Modernization Stakeholder Day III Advocacy and Comment Legislation Speed limiters, preemption, and Norton bill await possible lame duck action Although...

Regulatory and Legislative Update - August 2024

Contents Regulation and Enforcement FMCSA supports legislation to assess penalties for unlawful brokerage FMCSA Holds Final Listening Session on SFD Initiative FMCSA pushes back timing of various rulemaking proceedings DOT’s artificial intelligence head named FMCSA deputy administrator Company loses exemption bid for additional driving time FMCSA denies HOS exemption for drivers hauling cement FMCSA removes four devices from list of registered...

WHAT IS HOT SHOT TRUCKING? AKA HOTSHOT TRUCKING

Modern business is all about strict timelines. Whether your field is manufacturing, extraction, retail, or research and development, your operations are bound to rely on activities that operate in tandem. The most minor of supply shortages can throw these activities off, potentially costing you thousands of dollars just for a few hours' delay. Success thus hinges on your ability to right the ship as quickly as possible after a supply shortage arises.

Industries We Serve

Modern day hot shot trucking provides the speed and exclusivity you need to meet the most demanding and time-sensitive shipping requirements. We use every resource, avenue, and channel available to ship your freight by ground or air. Designed specifically to address supply and distribution problems that arise without warning, hotshot trucking tactics involve coordinating a network of carriers in a variety of locations. By calling on the vehicles closest to your supply or distribution points, hotshot brokers can fill any sudden gaps in your supply network almost as soon as they happen. This minimizes the disruption to your business and allows you to quickly return to ordinary operations, weathering the storm without skipping a beat.

Automotive

The automotive supply chain already has significant challenges. Don’t let malfunctioning equipment stop the production line. Step on the gas with HotShotTrucking.com’s suite of services that will get you back in the fast lane. With HotShotTrucking.com, companies are devising shipping strategies to swiftly deliver critical parts and equipment — whether it's ground expedite service with sprinter vans, box trucks and 53-foot tractor trailers or air freight and air cargo.

Aviation & Aerospace

Every moment a commercial airliner sits on the ground, it costs an airline money. Expedited freight services by HotShotTrucking.com can get you back in the air with prompt delivery of parts and equipment throughout North America. We are equipped with the expertise to navigate the complexities of shipping jet engines and other types of loads, and our network of hot shot drivers has extensive experience transporting aviation assets.

Construction

One shipping delay can snowball and cause delays throughout your entire project. You need an experienced 3PL provider who understands the construction industry and has the logistical reach to deliver your freight on time, anywhere. That 3PL partner is HotShotTrucking.com. Whether in the air or on the ground via truck and trailer, we can connect companies to expedited freight services for the prompt delivery of parts and equipment throughout North America.

Mining & Metals

From cranes to chemicals to excavators to conveyor belts, HotShotTrucking.com has the experience and industry know-how required for shipping sensitive, oversized, and hazardous equipment. Third-party hot shot trucking and logistics providers such as HotShotTrucking.com specialize in devising and implementing innovative shipping solutions, ensuring mines can swiftly return to operation. We’ll pick up your shipment, deliver it to the airport and receive it at the other end – providing hand-carried service as necessary or required.

Manufacturing

Every moment a manufacturing facility or factory sits idle costs a company money because of the high costs involved. With many manufacturers building to only just-in-time production rates, any disruption threatens parts and vehicle inventories. This is where the speed and expertise of freight services from HotShotTrucking.com can make a difference throughout the entire manufacturing supply chain. We do all the logistical legwork to find the optimal solution for your job, whether it's an exclusive air charter or expedited ground shipping.

Telecommunications

From servers to cell towers, information, voice, and data must flow to keep businesses, production, and the public online and connected. When equipment goes dark, depend on HotShotTrucking.com to get your systems flashing green again. This is where the speed and experience of trucking and freight services from HotShotTrucking.com can help. Our hot shot truck network excels at the prompt delivery of parts and equipment throughout North America.

Oil & Gas

The oil and gas industry faces challenging conditions in offshore and onshore oil rigs, often in remote locations with limited infrastructure. Don’t let oil pumps or pipelines sit idle waiting for equipment. By having the right plans, parts, people, and logistics partner like HotShotTrucking.com, you can effectively mitigate plant or pump downtime, unscheduled disruptions, and equipment failures.

Cost of Urgent Shipping

Which of our specialized shipping services best fits your needs?

Blog and Resource Center

How AirFreight.com Solved a PGA Tour Shipping Emergency

Learn how AirFreight.com located a lost shipment and helped save the PGA Golf Tour.

How AirFreight.com Saved The Farm By Solving A Major Shipping Delay

Learn how we saved a Montana-based artisanal farm thousands of dollars by expediting a shipment of perishable goods.

Expedited Shipping Vendor Comparison

We’ve done the research for you. This vendor comparison sheet breaks down how AirFreight.com stacks up against the competition.

talk to an expeditor now

Get a Quote in Minutes for Your Time-Critical Freight Needs

GET A QUOTE