June 25, 2024 | BY Dan Boaz

Hot Shot Flatbed

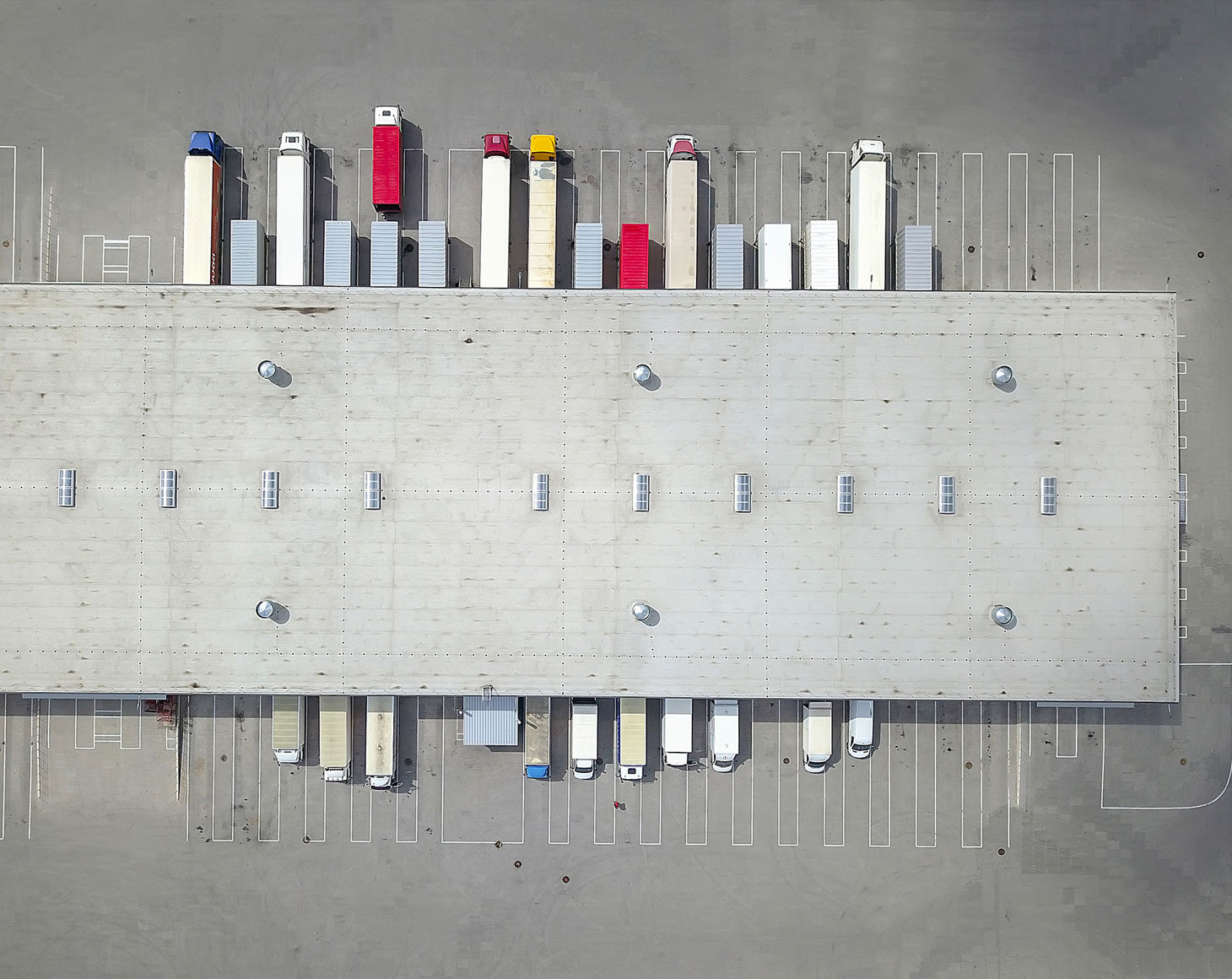

In the hot shot trucking industry, speed and reliability are paramount. Hot shot flatbed trucking is designed to meet urgent shipping needs.

Share this article

In this article we delve into the intricacies of hot shot flatbed services, exploring everything from the types of vehicles used to the role of technology in tracking and managing shipments.

UNDERSTANDING FLATBED TRUCKING

TALK TO AN EXPEDITOR NOW

Get a Quote in Minutes for Your Time-Critical Freight Needs

Cargo for Hot Shot Flatbed

Hot shot flatbed services are versatile, capable of transporting a wide range of cargo types. These include construction materials, machinery, plane and automotive parts, and other industrial goods. The open nature of the flatbed trailer allows for easy loading and unloading, accommodating oversized or irregularly shaped cargo.

The standard 53-foot tractor trailer boasts a load capacity of up to 48,000 pounds, though this can vary depending on the type of flatbed used, offering significant economies of scale for any shipment. The maximum height of cargo that can be loaded onto a flatbed varies by trailer type and bed height, typically not exceeding 162 inches in total height. A typical flatbed trailer sits 5 feet above the ground and utilizes a combination of materials such as lumber, steel tarps, winch straps, transport chains, and binders to securely fasten the cargo. As long as your freight isn't hazardous, perishable, or sensitive to temperature changes, a 53-foot flatbed trailer proves to be an excellent choice for expedited transportation across states and even within states.

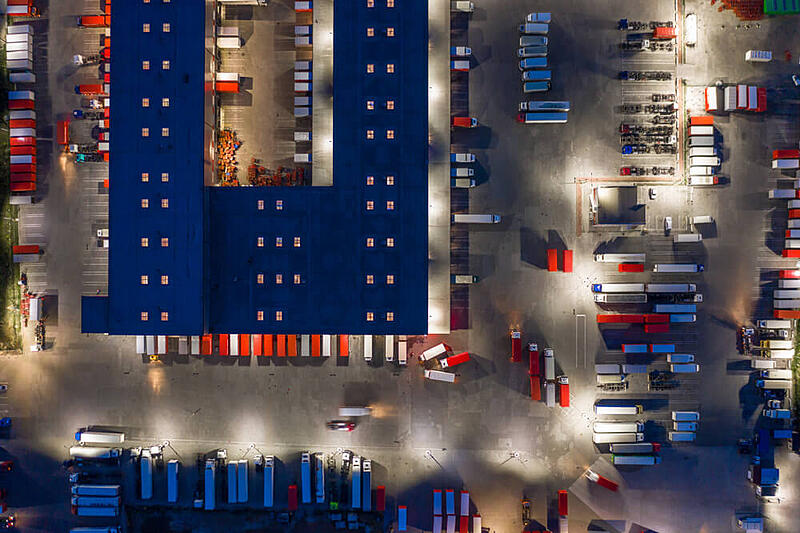

Optimizing Transport Logistics for Hot Shot Flatbed Services

Optimizing transport logistics is key to the success of hot shot flatbed services. Efficiency in operations can lead to faster delivery times, lower costs, and improved customer satisfaction. However, achieving this requires careful planning, coordination, and the use of technology.

Strategies for Fast and Reliable Freight Transport

Technology's Role in Tracking and Managing Shipments

Route Planning and Time Management

Vehicles and Trailers Used in Hot Shot Flatbed Trucking

The vehicles used in hot shot flatbed trucking are as diverse as the cargo they transport and include lowboy trailers, step deck trailers, sidekit trailers, gooseneck trailers and others. At HotShotTrucking.com, our seasoned expeditors carefully evaluate various types of flatbed trailers, each offering unique advantages for specific types of freight. This thorough assessment ensures we select the optimal flatbed trailer type for your shipment needs.

By matching trailer capabilities to your load’s exact dimensions, weight, and handling requirements, we minimize transit risk, eliminate costly over-dimensional permits whenever possible, and accelerate delivery timelines. Whether you’re moving tall industrial equipment that demands the lower deck height of a step deck, oversized machinery best suited to a lowboy, or palletized materials that benefit from the weather protection of a sidekit, our logistics specialists leverage a nationwide network of vetted flatbed carriers to secure the right equipment, confirm route feasibility, and coordinate real-time tracking—ensuring your freight moves safely, compliantly, and on schedule every time.

Safety and Compliance

Safety is paramount in hotshot trucking. From securing the load to ensuring the vehicle's roadworthiness, every aspect must be meticulously managed. Improperly secured cargo can shift during transit, posing a risk to the driver and other road users. Therefore, it's essential to use appropriate tie-downs and load securement devices, and to regularly check them during the journey.

Hot shot trucking is subject to various regulations and permits. These can include weight and size restrictions, driver hours of service rules, and special permits for transporting hazardous materials.

Our expeditors map legally approved routes, ensuring every hot shot load moves swiftly while remaining fully compliant with FMCSA rules, state DOT regulations, and hazardous-materials safety standards.

Choosing the Right Hot Shot Flatbed Service Provider

Choosing the right hot shot flatbed service provider is crucial for successful freight transport. When choosing a hot shot flatbed service, it's important to conduct a cost-benefit analysis. Building relationships with reliable carriers is key to ensuring consistent and high-quality service. These relationships can lead to preferential rates, priority service, and better communication. It's also important to maintain these relationships through regular communication, prompt payment, and mutual respect.

Beyond price, evaluate prospective carriers on safety scores, cargo-insurance limits, real-time tracking technology, and proven performance on lanes similar to yours; the incremental cost of a premium, fully insured operator is quickly offset by reduced claim risk, shorter transit times, and higher on-time percentages.

Future Trends in Hot Shot Trucking

The hot shot trucking industry is constantly evolving, driven by technological advancements and changing market demands. Looking ahead, transport logistics is set to become even more complex and dynamic. Advancements such as autonomous vehicles, drone delivery, and technology for supply chain transparency are likely to reshape the industry. For hot shot flatbed services, staying ahead of these trends and adapting to changes will be crucial for continued success and growth.

By proactively embracing these innovations today, we ensure our customers reap the benefits of tomorrow’s hyper-efficient, ultra-transparent hot shot supply chain.

Our Process lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis.

Value prop lorem ipsum

Ut posuere hendrerit nisl metus neque. Facilisis quis adipiscing a molestie. Tempor turpis tincidunt nulla diam in. Nec etiam ut neque placerat mauris nulla. Semper hendrerit at urna orci in faucibus sit lacus. Tincidunt fermentum consequat.

SEE OTHER CITIES WE SERVICE IN THIS STATE

Value prop lorem ipsum

Ut posuere hendrerit nisl metus neque. Facilisis quis adipiscing a molestie. Tempor turpis tincidunt nulla diam in. Nec etiam ut neque placerat mauris nulla. Semper hendrerit at urna orci in faucibus sit lacus. Tincidunt fermentum consequat.

SEE OTHER CITIES WE SERVICE IN THIS STATE

Industries That Rely on Flatbed Trucking Services

- Manufacturing & Heavy Machinery

- Energy (Oil, Gas & Renewables)

- Construction & Infrastructure

- Agriculture & Forestry

- Defense & Aerospace

Manufacturing & Heavy Machinery

OEMs routinely ship presses, injection-molding units, and CNC machines that dwarf standard vans. Step-decks, RGNs, and other flat bed trucks let factories crane these assets straight onto the deck or roll them up detachable ramps—no costly teardown required. Because downtime at the destination plant is expensive, shippers demand a flatbed trucking company with low claims ratios, high cargo-insurance limits, and proven blocking-and-bracing skill. Demand stays steady all year, but upgrades and plant moves trigger project surges that call for dedicated flatbed freight capacity and tight coordination with riggers and millwrights.

Energy (Oil, Gas & Renewables)

From drilling rigs to wind-tower sections, energy projects depend on flatbed truck freight. Remote oil pads may need daily hot-shot resupply, while renewable developers hire extendable decks and multi-axle lowboys to haul nacelles, tower sections, and rotor blades. Because project schedules swing with commodity prices and tax-credit deadlines, a flexible trucking service—able to pivot from routine pipe moves to escort-required superloads—is essential.

Construction & Infrastructure

Job sites consume steel beams, rebar, lumber, and concrete forms that simply will not fit inside a dry van. Flatbed trucks allow cranes or forklifts to set material exactly where crews need it, even when there’s no dock. Activity peaks in spring and summer, so contractors favor flatbed trucking fleets that can scale capacity fast, supply Conestogas for weather protection, and keep on-time performance high enough to prevent costly site delays.

Agriculture & Forestry

Farmers and equipment dealers book hot shot flatbed trucking for tractors, combines, and irrigation pipe that must reach the field before planting or harvest. Loggers use rugged flat bed trucks to haul timber and sawmill machinery out of remote forests. Because many loads are short-haul and time-critical, producers look for flatbed companies near me that know rural roads, secure odd-shaped cargo safely, and hit multiple stops per day without sacrificing schedule.

Defense & Aerospace

Armored vehicles, satellite housings, and oversized wing assemblies exceed van dimensions and demand air-ride, low-deck equipment plus stringent security. Only a handful of vetted flatbed trucking companies hold the clearances, safety scores, and specialized gear to move these high-value assets. Real-time tracking, strict chain-of-custody, and precise routing keep military and aerospace freight moving on deadline—even when blackout procedures apply.

Frequently Asked Questions

What is flatbed trucking and when is it used?

Which industries commonly use flatbed trucking services?

What types of cargo are typically shipped on flatbed trailers?

What are the different types of flatbed trailers and their uses?

When should I use a step deck trailer instead of a standard flatbed?

What is a Conestoga flatbed trailer and what are its advantages?

What are the standard dimensions of a flatbed trailer (length, width, height)?

What is hot shot flatbed trucking and when is it useful?

What are oversize flatbed loads and how are they handled?

How do I arrange a flatbed freight shipment?

Arranging a flatbed shipment involves a few key steps, and it can be done either through a freight broker/3PL or by contacting flatbed trucking companies directly. Here’s a general process:

-

Gather shipment details: First, you need to know the specifics of what you’re shipping – the dimensions (length, width, height) of the load, the weight, and the nature of the cargo (e.g., steel beams, machinery, crates). Also identify if it requires any special handling, such as tarping (for weather protection) or if it’s oversize (needing permits). Precise details are crucial because flatbed carriers use this information to determine equipment needs and quote the job.

-

Choose a carrier or broker: If you have known flatbed trucking companies you’ve worked with, you can reach out to them for a quote. Many shippers rely on brokers or logistics providers to find a suitable flatbed, especially if they don’t have a regular carrier or if the lane is unusual. A freight broker will have access to a network of flatbed carriers and can match your load with available trucks. Provide the broker or carrier with your shipment details, origin and destination addresses, and your timeframe for pickup and delivery.

-

Get a quote and book: The carrier or broker will give you a freight rate quote based on factors like distance, load size, complexity, and current trucking rates. Once you agree on the cost and terms, you’ll formally book the shipment. At this stage, you should clarify any requirements such as pickup appointment times, whether you need the driver to have specific PPE or equipment, and if any special instructions apply.

-

Prepare for pickup: Ensure the pickup location is ready – e.g., the material is staged for loading, and the necessary loading equipment (forklift, crane) is available. Flatbed drivers don’t typically provide loading machinery; that’s up to the shipper/consignee. However, the driver will position the truck for loading and assist in securing the freight. Have any required permits on hand if it’s an oversize load (though carriers usually handle obtaining permits, you may need to coordinate timing).

-

During loading: Work with the driver to get the cargo placed correctly on the trailer. The driver will then secure the load using straps, chains, and binders as appropriate (shippers often observe this to ensure any specific securement preferences are met, but drivers know DOT securement rules). If tarping was requested (to protect the freight from weather), the driver will apply tarps once loaded.

-

Transit and delivery: Once loaded and all documentation (like the bill of lading) is signed, the flatbed shipment is on its way. Good communication is important – ask the carrier how you can track the shipment or get updates. On the day of delivery, make sure the receiving site is prepared with unloading equipment, since flatbeds require a forklift or crane to offload if there’s no dock. The driver will remove straps/chains and tarps before unloading. After delivery, you’ll receive a proof of delivery.

In summary, to arrange a flatbed shipment you’ll provide details, secure a carrier or broker, book the load with a agreed rate, and ensure proper loading/unloading arrangements. It’s also a good practice to verify the carrier’s insurance and safety rating (especially if working directly) and to clearly communicate any special needs up front. Planning and accurate information are key to a smooth flatbed shipping process.

Related Blog Posts

What is Hot Shot Trucking?

Hot shot trucking is a specialized freight service focused on speed, flexibility, and delivering time-critical hot shot loads. Hot shot trucking services involves hauling smaller, urgent shipments on short notice and delivering them directly to their destination as fast as possible.

.jpg?width=960&length=960&name=shutterstock_6919525%20(1).jpg)

Hot Shot Trucking Texas

Hot shot trucking is not just a logistical solution. It is an economic imperative in Texas. Hot shot services are essential in supporting businesses across the state, from oil and gas operations to small local enterprises. Moreover, it plays a crucial role in disaster relief and emergency situations. By ensuring rapid delivery of essential supplies, hotshot trucking becomes a lifeline in times of crisis. This article aims to provide a...

Houston Hot Shot Delivery

Houston’s position as a national energy hub means urgent shipping needs are commonplace. When a critical piece of equipment fails in an oilfield or at a refinery, hot shot delivery services become a supply-chain lifeline for the Houston economy. Hot shot trucking is a niche but vital segment of the trucking industry, specializing in rapid, on-demand transport of smaller, time-sensitive freight loads. In a logistics hub like Houston hot shot...

Texas Trucking Company

Hot shot trucking companies in Texas specialize in hauling smaller, time-sensitive loads—often for the energy sector, where timing is crucial. From providing hot shot delivery services to offering competitive freight quotes, these companies are integral to the world of Texas logistics. In addition to their speed and accessibility, hotshot trucking companies in Texas offer a cost-effective alternative to larger freight services for small to...

Trucking Companies in Michigan

From Detroit to the Upper Peninsula, get hot shot trucking and expedited freight handled with safety-first drivers, rapid dispatch, and real-time shipment visibility.

Midwest Winter Weather and Expedited Freight

Winter weather in the Midwest can bring freight shipping to a standstill, turning routine routes into major challenges. HotShotTrucking.com’s hot shot trucking and expedited freight services keep supply chains moving even when snow and ice threaten to shut down logistics.

How to Start a Hotshot Trucking Business

Today we're diving deep into how to get started in hotshot trucking. If you're looking for a way to enter the trucking industry with lower startup costs and more flexibility, hotshot trucking might be the perfect fit for you. We'll walk you through the key steps to launch your hotshot trucking business, from understanding what it is to finding your first loads. We’re an expedited freight company that works with hotshot truckers all across North...

Trucking Companies in Texas

Texas boasts one of the largest and fastest-growing economies in the world, powered by industries from energy and manufacturing to technology and agriculture. In fact, if Texas were its own country it would rank around the eighth-largest globally by GDP. This economic might creates enormous demand for freight transportation. Thousands of trucking companies in Texas operate around the clock to keep factories running, store shelves stocked, and...

Hot Shot Trucking and Cross-Border Logistics in Texas

The Texas-Mexico border is the busiest trade gateway in North America. Every day, thousands of trucks shuttle across international bridges in Texas, carrying auto parts, aerospace components, electronics, and other high-value goods between the United States and Mexico.

Connecting Tennessee’s Automotive Industry with Mexico

Tennessee has emerged as an automotive manufacturing powerhouse, home to major assembly plants and a vast network of over 900 suppliers across the state. From Nissan’s sprawling operations in Smyrna and Decherd to Volkswagen’s high-tech plant in Chattanooga and General Motors’ extensive facilities in Spring Hill, the Volunteer State produces hundreds of thousands of vehicles annually.

Truckload Demand Remains Higher than this Time Last Year

Based on the latest reports on durable goods manufacturers’ shipments, orders and inventories, freight volume has yet to decline. The most recent numbers from the US Census Bureau show that orders for manufactured durable goods increased in May by 0.7% to $267.2 billion. This follows increases for seven of the past eight months. This May, shipments of manufactured durable goods increased by $3.6 billion or 1.3%, followed by a 0.3 % rise in...

The Advantages of Hot Shot Trucking for Small Businesses

In the world of logistics, small businesses often face unique challenges when it comes to shipping their products efficiently and cost-effectively. This is where hot shot trucking can be a game-changer. Hot shot trucking offers a range of advantages that can significantly benefit small businesses, enabling them to compete in the marketplace and meet customer demands. In this blog post, we will explore the advantages of hot shot trucking for...

WHAT IS HOT SHOT TRUCKING? AKA HOTSHOT TRUCKING

Modern business is all about strict timelines. Whether your field is manufacturing, extraction, retail, or research and development, your operations are bound to rely on activities that operate in tandem. The most minor of supply shortages can throw these activities off, potentially costing you thousands of dollars just for a few hours' delay. Success thus hinges on your ability to right the ship as quickly as possible after a supply shortage arises.

Industries We Serve

Modern day hot shot trucking provides the speed and exclusivity you need to meet the most demanding and time-sensitive shipping requirements. We use every resource, avenue, and channel available to ship your freight by ground or air. Designed specifically to address supply and distribution problems that arise without warning, hotshot trucking tactics involve coordinating a network of carriers in a variety of locations. By calling on the vehicles closest to your supply or distribution points, hotshot brokers can fill any sudden gaps in your supply network almost as soon as they happen. This minimizes the disruption to your business and allows you to quickly return to ordinary operations, weathering the storm without skipping a beat.

Automotive

The automotive supply chain already has significant challenges. Don’t let malfunctioning equipment stop the production line. Step on the gas with HotShotTrucking.com’s suite of services that will get you back in the fast lane. With HotShotTrucking.com, companies are devising shipping strategies to swiftly deliver critical parts and equipment — whether it's ground expedite service with sprinter vans, box trucks and 53-foot tractor trailers or air freight and air cargo.

Aviation & Aerospace

Every moment a commercial airliner sits on the ground, it costs an airline money. Expedited freight services by HotShotTrucking.com can get you back in the air with prompt delivery of parts and equipment throughout North America. We are equipped with the expertise to navigate the complexities of shipping jet engines and other types of loads, and our network of hot shot drivers has extensive experience transporting aviation assets.

Construction

One shipping delay can snowball and cause delays throughout your entire project. You need an experienced 3PL provider who understands the construction industry and has the logistical reach to deliver your freight on time, anywhere. That 3PL partner is HotShotTrucking.com. Whether in the air or on the ground via truck and trailer, we can connect companies to expedited freight services for the prompt delivery of parts and equipment throughout North America.

Mining & Metals

From cranes to chemicals to excavators to conveyor belts, HotShotTrucking.com has the experience and industry know-how required for shipping sensitive, oversized, and hazardous equipment. Third-party hot shot trucking and logistics providers such as HotShotTrucking.com specialize in devising and implementing innovative shipping solutions, ensuring mines can swiftly return to operation. We’ll pick up your shipment, deliver it to the airport and receive it at the other end – providing hand-carried service as necessary or required.

Manufacturing

Every moment a manufacturing facility or factory sits idle costs a company money because of the high costs involved. With many manufacturers building to only just-in-time production rates, any disruption threatens parts and vehicle inventories. This is where the speed and expertise of freight services from HotShotTrucking.com can make a difference throughout the entire manufacturing supply chain. We do all the logistical legwork to find the optimal solution for your job, whether it's an exclusive air charter or expedited ground shipping.

Telecommunications

From servers to cell towers, information, voice, and data must flow to keep businesses, production, and the public online and connected. When equipment goes dark, depend on HotShotTrucking.com to get your systems flashing green again. This is where the speed and experience of trucking and freight services from HotShotTrucking.com can help. Our hot shot truck network excels at the prompt delivery of parts and equipment throughout North America.

Oil & Gas

The oil and gas industry faces challenging conditions in offshore and onshore oil rigs, often in remote locations with limited infrastructure. Don’t let oil pumps or pipelines sit idle waiting for equipment. By having the right plans, parts, people, and logistics partner like HotShotTrucking.com, you can effectively mitigate plant or pump downtime, unscheduled disruptions, and equipment failures.

Cost of Urgent Shipping

Which of our specialized shipping services best fits your needs?

Blog and Resource Center

How AirFreight.com Solved a PGA Tour Shipping Emergency

Learn how AirFreight.com located a lost shipment and helped save the PGA Golf Tour.

How AirFreight.com Saved The Farm By Solving A Major Shipping Delay

Learn how we saved a Montana-based artisanal farm thousands of dollars by expediting a shipment of perishable goods.

Expedited Shipping Vendor Comparison

We’ve done the research for you. This vendor comparison sheet breaks down how AirFreight.com stacks up against the competition.

talk to an expeditor now

Get a Quote in Minutes for Your Time-Critical Freight Needs

GET A QUOTE